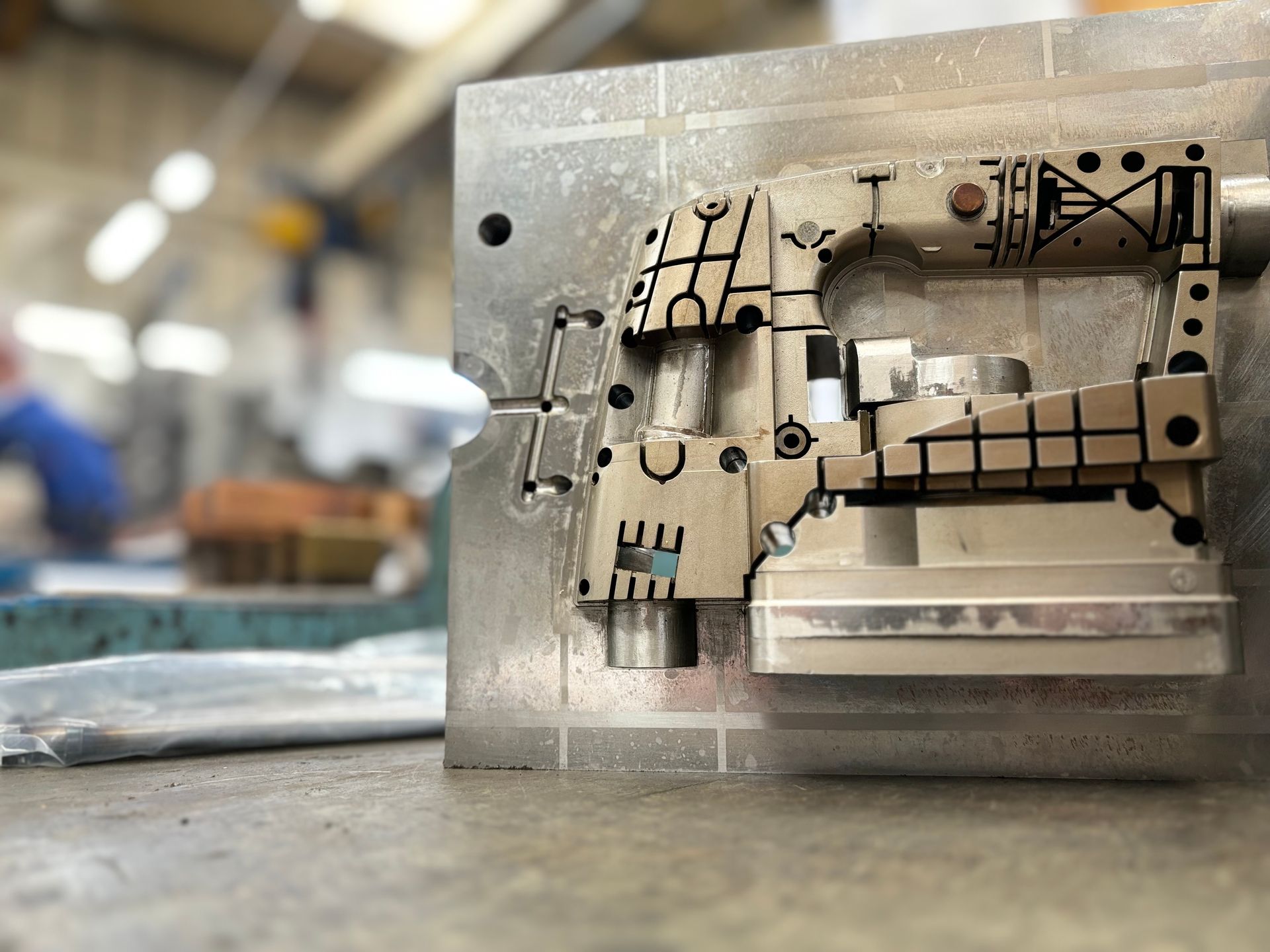

RUBBER MOULD TOOLING

Precision and Quality

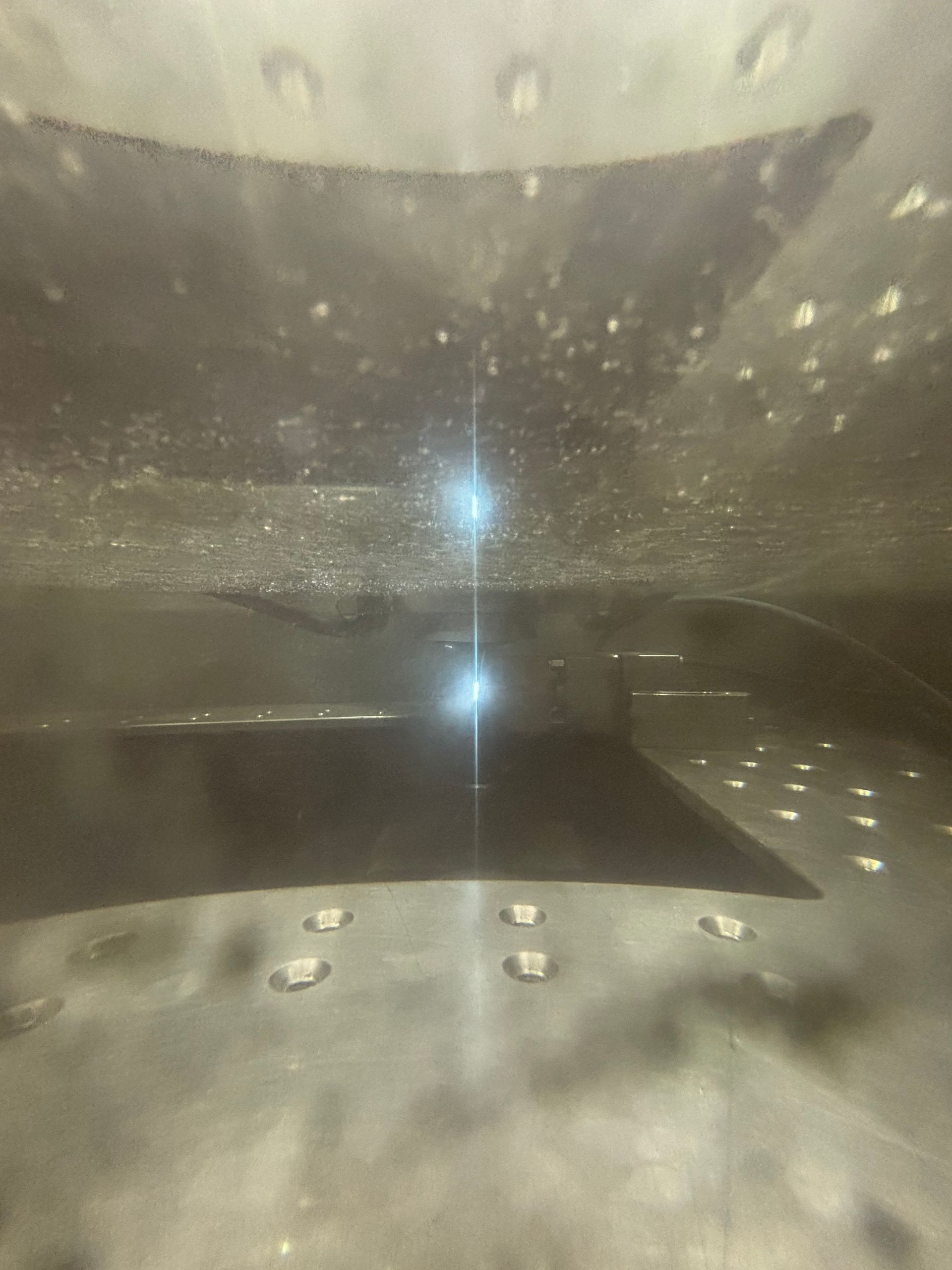

The different methods for rubber moulding all involve a unique approach, but each one begins with the creation of a high-precision mould.

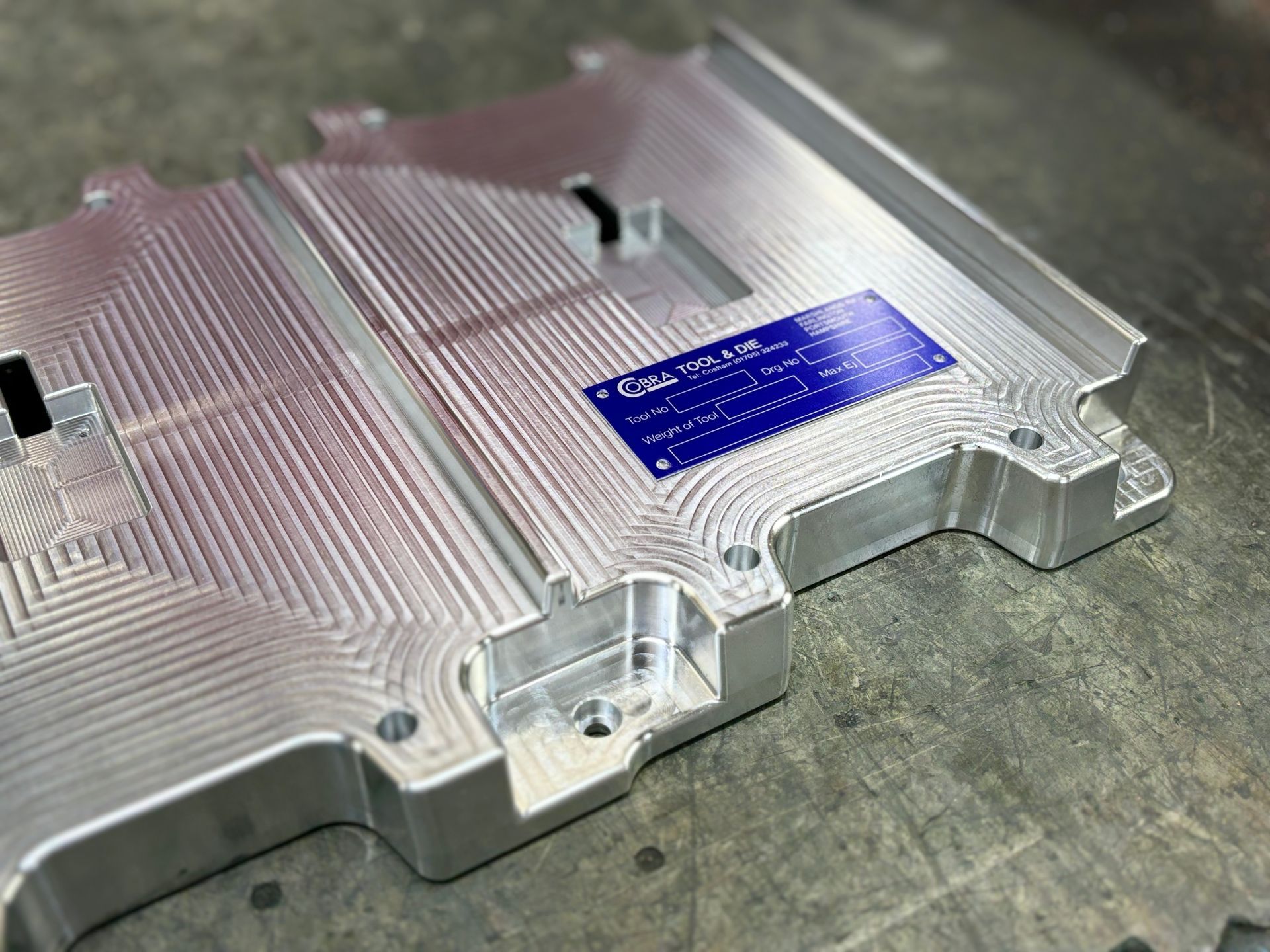

Cobra Tool & Die use a full range of CNC milling and spark erosion machines to deliver the highest quality standards in custom rubber mould tool production.

With a manufacturing capacity of up to 2 tonnes, we can produce single or multi-cavity tooling.

- Compression Moulds

- Transfer Moulds

- Injection Moulds

From high-spec gaskets to deep-sea multi-layer sealing joints, we have the expertise to provide a top-quality, efficient and reliable product development, design and manufacturing service from start to finish.

RUBBER MOULD TOOL PRODUCTION

For efficiency and precision, Cobra's in-house design and manufacturing capabilities for rubber mould tools

give our clients a competitive advantage

Compression Moulds

Cost-effective and precise

Cobra Tool & Die produces compression mould tools for an extensive range of items, from seals and gaskets to larger parts for industrial purposes.

Compression moulding is particularly suited for materials such as rubber, thermosetting composites, and many others.

This technique is simple, precise and effective. It is especially advantageous for high-volume production as the cost of moulds is relatively lower than the cost of those used in other methods, such as injection moulding.

Another advantage of compression moulding for rubber moulds is that it effectively reduces material wastage, helping to save unnecessary expenses.

Transfer Moulds

For more intricate designs

When dimensional tolerances are critical for rubber components, transfer moulding is often chosen due to the high level of precision that it offers.

During the transfer moulding process, rubber is introduced into a chamber and transferred into the mould cavity under pressure.

As specialist manufacturers of rubber mould tools, Cobra Tool & Die are equipped with the design and production expertise to deliver the highest-quality results.

Transfer mould tools can be designed on site and are manufactured in our fully equipped tool room, meaning our customers benefit from the efficiency of in-house project management and optimal lead times.

Injection Moulds

Efficiency for mass production

Injection moulding is a process often chosen for the production of high volumes of components.

As a UK-based toolmaking firm, Cobra Tool & Die produces injection mould tools for various industries, from automotive, aviation and medical components to electronics and consumer goods.

Injection mould tool production involves creating precise moulds used to shape materials, typically plastics, into specific forms through an injection process.

The production time for an injection mould tool can be from around 2 to 10 weeks depending on the complexity and the volume involved. Generally, projects with shorter lead times include rubber moulds and prototypes. For a more complex project, contact us to discuss your requirements.

Reliability, Accuracy, & Precision

Over the years, the tools produced by us have given our customers many years of accurate, precise and reliable use.

Built To Last

Our rubber mould tools use the best components and are built to last.

We're Expert Toolmakers

We have decades of experience, knowledge and expertise in toolmaking. We also offer a rapid refurbishment service to ensure that downtime is kept to a minimum as and when required.

Contact Us

If you would like to discuss your toolmaking needs, whether that’s innovation, concept design, new tooling or repairs, get in touch with us to find out more about what we can offer you. Give us a call, or why not pop in and see us!

All Rights Reserved | Cobra Tool & Die Ltd